Elgiloy Springs

Custom Elgiloy Springs

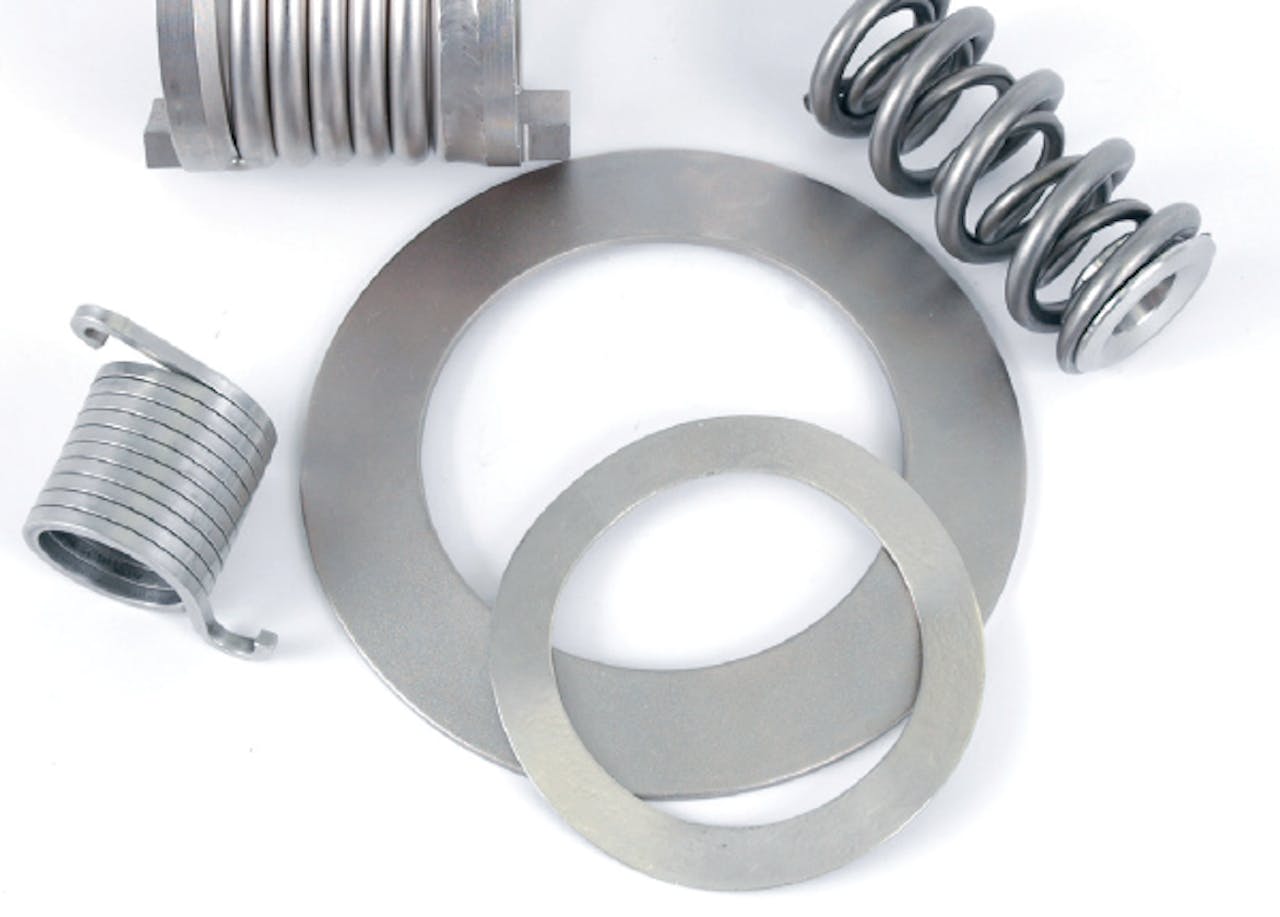

We manufacture custom Elgiloy springs from wire and strip material. With over three decades of experience, our expert team works with your engineers to review product drawings and control manufacturing so you get the Elgiloy spring you need, especially for difficult applications such as those that have severe service requirements. We also maintain a large inventory of raw in-stock Elgiloy material. Typical Elgiloy springs we produce include:

- Custom springs

- Compression springs

- Flat, bow, and drag springs

- Garter springs

- Bellevilles

We specialize in applications that have severe service needs. For more details or to work with one of our engineers to solve a complex problem, request a quote.

Why Elgiloy Springs?

Elgiloy springs offer many benefits including corrosion resistance, superior strength, malleability, and long fatigue life. Elgiloy is often chosen in high-temperature and high-stress applications since the material is known for its resistance to stress, corrosion, cracking, pitting, and performance in extreme temperatures (up to 850°F). Elgiloy is an alloy composed of cobalt, chromium, nickel, iron, molybdenum, and manganese.

Elgiloy Spring Applications

Due to its high strength and performance in extreme temperatures and corrosive environments, Elgiloy springs are often found in oil and gas, aerospace, and medical applications.

Typical Elgiloy Spring Applications:

- Rocket Motors

- Gas Turbines

- Nuclear Reactors

- Sealing Gaskets

- Chemical Processing

- Medical Equipment (Stents, Pacemakers, and Surgical Clips)

Considerations for Using Egiloy (UNS R3003)

Cost

Cost can be prohibitive if the performance requirements do not merit its use. If cost is a concern and high-temperatures resistance is not needed, other materials like MP35N may be preferable for the application.

MP35N vs Elgiloy

MP35N and Elgiloy are often used interchangeably, except when extremely high temperatures are required. For requirements above 400°F, Elgiloy is recommended. Visit our MP35N page to learn more about MP35N Springs and other MP35N products that are recommended for applications that don't require extremely high temperature resistance.

Elgiloy Springs & Other Elgiloy Parts

Elgiloy springs are ideal for applications that require high strength and corrosion resistance, including oil and gas, marine applications, medical devices, and aerospace. In addition to elgiloy springs, Engineered Spring Products also produces a variety of machined parts, stampings, and other custom parts. We specialize in manufacturing custom parts from specialty materials including MP35N, Elgiloy, Inconel, and more.

Below are some of the parts ESP or other MW Components brands produce using Elgiloy. Looking for something that isn't on this list? Contact us for a custom quote.

- Compression Springs

- Extension Springs

- Torsion Springs

- Double Torsion Springs

- Flat Springs / Bow Springs

- Belleville Washers / Disc Springs

- Garter Springs

- Snap Rings

- Stamped Parts / Custom Metal Stamping

- Other Custom Parts