Medical Springs

Metal Springs for Medical & Pharmaceutical Devices

MW Components is a medical spring manufacturer providing a wide variety of springs types and materials for use in the medical industry. We supply springs at the highest quality standards, including ISO9001, and are experts in a variety of medical grade materials such as 316 stainless steel. We offer low MOQs, full lifecycle support from prototype to production, and in-house services such as heat treating, coating, and plating.

Request a quote for custom parts, or shop our stock and standard parts online.

Why Choose MW for Medical Springs?

With over 100 years of experience, we're trusted by the largest global medical and pharmaceutical OEMs for both stock and custom springs.

40,000+

Spring Designs In-Stock

Unlimited

Custom Capabilities

20+

Locations in the USA

100+

Engineering & Design Experts

Rapid Prototyping

For Custom Medical Springs

100% Inspections

With Advanced Imaging

Specialty Materials

For Medical Applications

Dedicated Support

Live Reps at Each Location

About Medical and Pharmaceutical Springs

Metal springs, including coil springs, flat springs, and disc springs, play a crucial role in medical applications. Their utility in this field ranges from enhancing the functionality of medical devices to improving patient outcomes through innovative technologies.

Medical springs function differently depending on the application, but they are frequently used to provide movement such as compression and extension, within tightly controlled constraints. Because they are used in life-saving devices, medical springs must meet strict requirements in regard to materials, manufacturing methods, and specifications. Most medical and pharamaceutical springs are sourced from well established, reputable spring manufacturers who are known for quality and consistency.

Medical Spring Applications

Springs are used in everything from wheelchairs to implantable drug delivery devices and drug reservoirs. Below are just a few common applications for medical and pharmaceutical springs, although the full list of applications is much more extensive.

Drug Delivery Springs

One of the most notable applications of springs is in drug delivery devices. In devices like insulin pens or auto-injectors, coil springs provide the necessary force to deliver precise doses of medication. These springs ensure that the drug is administered efficiently and consistently, a critical factor in managing chronic conditions such as diabetes. The reliability of coil springs in these devices contributes to patient safety by minimizing dosage errors and improving overall ease of use. Drug delivery springs are also use din inhalers and drug reservoirs that are implanted in a patient's body to provide the best long-term outcome available.

Medical Equipment & Devices

Springs are integral to everything from common hardware such as wheelchairs and hospital beds to various diagnostic and therapeutic tools. For example, in blood pressure monitors, coil springs are used in the mechanism that inflates the cuff. This mechanism must be precise to ensure accurate readings. Similarly, in certain types of medical imaging equipment, such as MRI machines, coil springs help in the adjustment and stabilization of components, ensuring optimal imaging quality and patient comfort.

Surgical Robotics

Surgical robotics, which have revolutionized minimally invasive surgeries, also benefit from medical springs. In robotic surgical systems, springs are used in joint mechanisms and actuators that provide the dexterity and precision required for complex procedures. These springs help in the smooth operation of robotic arms and tools, facilitating delicate movements and reducing the risk of human error during surgery. The flexibility and strength of springs make them ideal for the intricate mechanical demands of robotic surgery.

Dialysis Machines

Dialysis machines, essential for patients with kidney failure, use springs in various components such as fluid handling systems and pump mechanisms. The springs assist in maintaining consistent fluid flow rates and pressures, which is vital for effective dialysis treatment. By ensuring stable operation, coil springs contribute to the machine’s reliability and the patient’s comfort during the procedure.

Types of Springs Used in Medical Devices

Medical device springs span the range of spring configurations, but some of the most common include:

- Medical compression springs

- Medical extension springs

- Medical torsion springs

- Medical disc springs

- Medical flat springs

Many medical device springs are made from 316 stainless steel, a material that has excellent corrosion resistance, is easy to clean, and has superior forming ability. For more information on medical grade 316 springs, download the flyer or shop our in-stock parts.

Medical Spring Manufacturing

Springs are versatile components with significant applications in the medical field. They enhance the functionality of drug delivery devices, improve the accuracy of medical equipment, enable precision in surgical robotics, and support the effective operation of dialysis machines. Their ability to provide reliable force, flexibility, and precise control makes them invaluable in advancing medical technology and improving patient care.

Medical springs are typically sourced directly from a spring or metal component manufacturer who has expertise in producing individual parts that are later incorporated into a larger device. Depending on their end use, medical springs must be manufactured to exacting standards. For example, drug delivery springs must provide exactly the amount of medical needed - no more and no less - to avoid causing unintended data to the patient. To ensure performance, the spring must be manufactured with the exact length, number of coils, and spring rate needed for the design. Quality control is essential to confirm that only quality parts without defects are passed on to the final device manufacturer. Because of this, most medical springs are sourced from manufacturers with experience in springs or medical component manufacturing.

For more information on medical springs, please contact us. MW Components has dozens of facilities across the United States and decades of experience in manufacturing for the medical industry.

Shop Medical 316SS Compression Springs

We have nearly 8,000 compression spring designs available in medical-grade 316 stainless steel. In-stock parts ship the same day.

Click to filter results by diameter, free length, and more. Filter Results

All Medical Spring Types

-

Coil springs are made from wire wound in a helix. They come in a variety of styles, including regular, tapered, variable rate, and more.

-

The most common type of medical spring, compression springs provide smooth movement with a precise amount of force.

-

Second only to compression springs, medical extension springs are commonly used in a wide variety of medical and pharmaceutical applications.

-

Medical torsion springs twist around around a central axis and can be produced with virtually any bend type or orientation.

-

In medical application, flat springs are often used as leaf springs or battery contacts in electrical devices.

-

Disc springs have the ability to generate high force in a concise spring length, making them ideal for many medical applications.

-

Machined springs are often used as a replacement for compression, extension, and torsion spring. You'll find them in medical foot pedals and robotic surgery systems.

-

Urethane springs are ideal in corrosive or magnetic environments and are often used as an alternative compression tool.

-

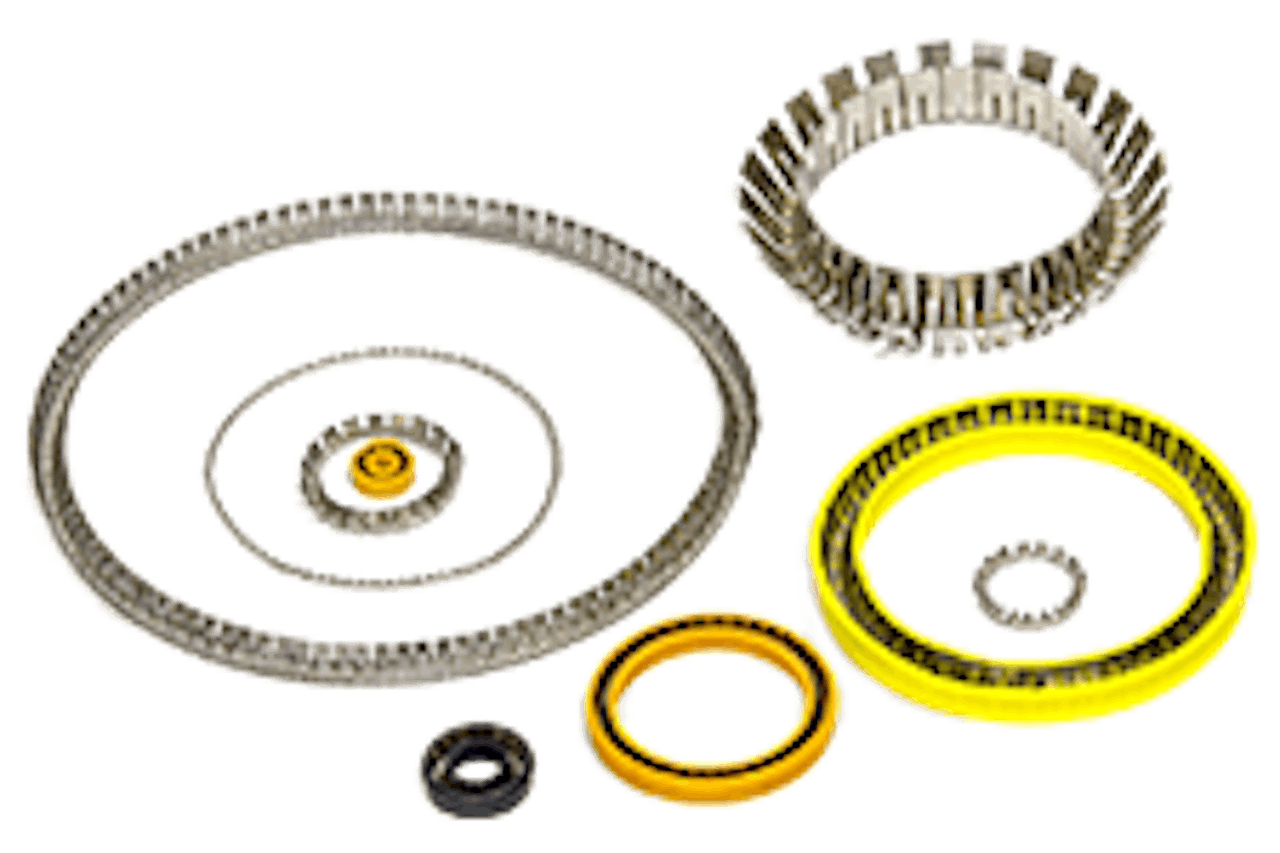

Seal spring energizers provide leak-proof seals and are used in the medical industry to protect against fluid ingress.

-

Canted coil springs are often help ground and shield against EMI and RFI in cable assembles for ultrasound applications.

Request a Custom Spring Quote

Most medical springs are one-of-a-kind designs. We manufacture parts to your specifications, ensuring the quality and performance that life-saving applications demand. Request a quote to partner with MW on your next project.