How to Select a Disc Spring

Disc springs, or Belleville washers, are cone-shaped discs that elastically deform to a shorter height when subjected to a load along the axis of symmetry. This elastic deformation characterizes the spring action. MW Components' Century Spring location offers a large selection of stock disc springs available for purchase online. Shop stock die springs online now or request a quote for custom springs.

About Our Disc Springs

Our disc spring fabrication is subject to exacting manufacturing and quality control standards. Materials used are generally in annealed condition and hardened to within a range of Rc 44-51 depending on material thickness. The standard material for Century Spring’s disc springs is high carbon C-1075 for general use at room temperature. All discs are preset so that they will not significantly relax under load over time.

Disc springs are used singly or in stacks to achieve a desired load and travel. In general, they function best under conditions requiring very high load in confined space or short travel. Under these constraints, it is often not practical or even possible to use a coil spring.

Century Spring also offers pre-stressed disc springs specifically sized for use with bolts (see part numbers beginning with “CDS”). The primary function of the disc in this application is to create a constant bolt load in bolted assemblies. Load compensation for differential expansion due to heat or dissimilar metals such as electrical connection bolting, or in wear situations, or when “torque- setting” is required are good examples of disc spring use.

Load Deflection Characteristics

The figure to the right, Load Deflection Characteristics of Disc Springs, can help you select the right spring for your application. For more details, please see page 420 in the Century Spring Catalog.

Disc Spring Load/Deflections For Various h/t Ratios

When the spring is loaded on its inside diameter so that it can be deflected beyond the flat position, the greatest possible deflection can be utilized. Since the load-deflection data beyond the flat position are symmetrical, the plot has been labeled so that loads may be determined for beyond the 100-percent flat position by reading it upside-down.

Using Disc Springs in Series and Parallel

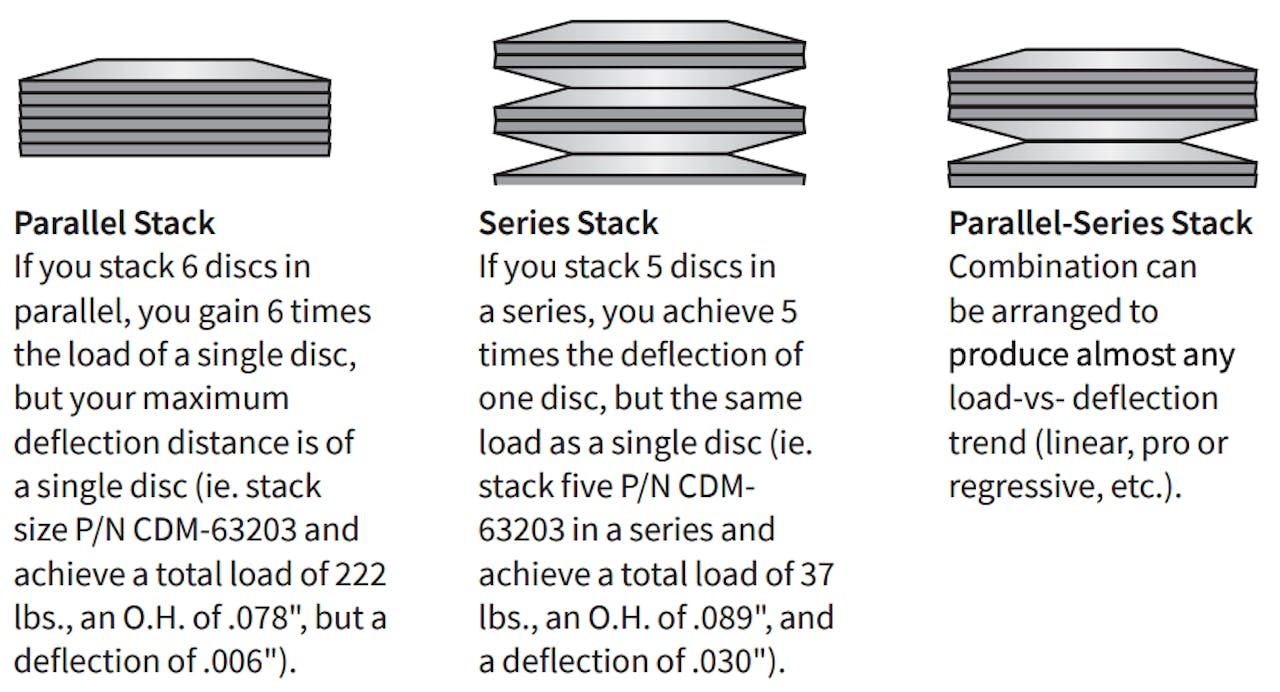

As a means of increasing the deflection or the load, disc springs can be used in series or parallel, or in a combination of series and parallel as shown in the figures on on the right. Deflection for a stack in series of identical discs is equal to the number of discs multiplied by the deflection of one, while the load is equal to the load carried by one disc. When the discs with an h/t ratio greater than 1.3 are used in a stack, the loaddeflection curve will be erratic as some discs will invert through the flat position.

In disc spring stacks, particularly those with parallel units, friction should be considered. Sliding friction is created at the disc’s adjoining, moving surfaces. As a result, the deflection which occurs when loading a stack of discs will lag as the stack is unloaded (hysteresis). This characteristic may be taken advantage of in shock or oscillatory loaded systems needing damping.

Contact Us

For further design and engineering resources, visit the MW Components resource center or for specific questions related to our products or services, contact us.